Transforming Legacy Challenges into Operational Triumphs: Toolrite’s Migration from PICK/MultiValue to Rover ERP

“Transitioning to Rover ERP has streamlined our operations, enhanced our communication, and enabled us to manage our vendors and data with unparalleled efficiency and systematic approach.”

Eric Kutemeier

Challenge

In the relentless tide of the digital era, businesses are feeling the urgency to adapt and modernize. Toolrite Manufacturing, an ambitious manufacturing company, found themselves hindered by the archaic constraints of their PICK/MultiValue system:

- The disorganized data storage of the legacy system made data extraction a daunting chore.

- Concerns over potential data loss loomed, with up to 40% of the data at risk during transition.

- Existing documentation, while comprehensive, lacked the precise details needed for daily operations, extending training durations.

- A heavy dependency on the knowledge of seasoned employees threatened operational continuity, complicating the onboarding process for newcomers.

Solution

Embracing the future, Toolrite Manufacturing underwent a transformation, transitioning to Rover ERP. This shift brought:

- EDI Integration: A significant value-add was the incorporation of Electronic Data Interchange (EDI), which drastically reduced manual data entry times, enhancing efficiency and accuracy.

- Advanced reporting tools enabling real-time data visualization and decision-making.

- Time-saving measures such as direct clock-in systems and integrated barcodes for precise time logging.

- Systematic documentation that not only preserved the knowledge of industry veterans but also reduced the learning curve for newcomers.

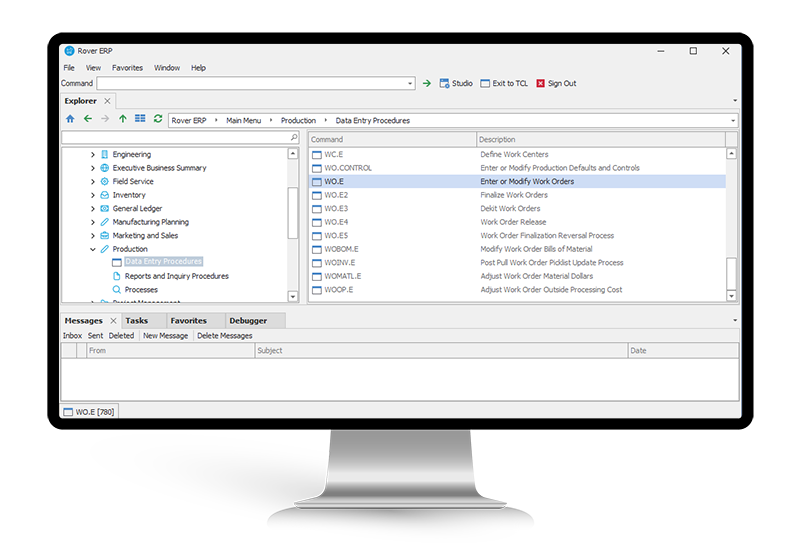

- Intuitive user interface designed with the modern user in mind.

- Tailored and scalable solutions to address Toolrite Manufacturing’s specific operational needs.

Impact

The switch to Rover ERP catalyzed numerous operational improvements:

- Streamlined Data Processes: With the integration of EDI, data entry became more seamless and efficient, saving countless hours and reducing potential for errors.

- Quicker and more informed decision-making due to dynamic data representation.

- Significant reduction in administrative errors thanks to efficient time management tools.

- A safeguarded reservoir of organizational knowledge, ensuring continuity and reduced dependence on a few key individuals.

- Accelerated training processes with role-specific documentation and a user-friendly interface.

- A system that grows with the company, thanks to Rover’s customization and scalability.

“Moving to Rover was like upgrading from a rotary phone to a smartphone. It’s an investment that benefits the entire team, streamlining our processes and enhancing efficiency.”

Eric Kutemeier – Toolrite Manufacturing Program Manager

Conclusion

In the narrative of digital evolution, Toolrite Manufacturing’s switch to Rover ERP emerges as a hallmark. It underscores the potential of digital platforms to rejuvenate businesses, ensuring they are agile, efficient, and primed for the challenges of tomorrow. Toolrite Manufacturing’s journey shines as a guiding star for enterprises seeking digital metamorphosis.